Dividing heads are essential tools for milling machines. They are used to divide a workpiece into equal parts and perform various machining operations on them. Choosing the right dividing head for your milling machine can be a daunting task. So, in this blog, we will discuss how to select the best semi-universal dividing head for milling machines.

1. Type of Work

The type of work you will be performing is the first thing to consider when choosing a semi-universal dividing head for your milling machine. For example, if you're doing heavy-duty work, a semi-universal dividing head with a high dividing ratio will be a good choice.

2. Accuracy

The accuracy of the semi-universal dividing head is critical when it comes to machining complex and precision parts. You should choose a dividing head that provides high accuracy.

3. Material

The material used for manufacturing the semi-universal dividing head is another important factor to consider. The dividing head should be made of high-quality materials to ensure durability and long-lasting performance.

4. Size

The size of the semi-universal dividing head should be appropriate for your milling machine. You should choose a dividing head that can handle the weight of the workpiece comfortably.

5. Speed

The speed at which the semi-universal dividing head operates is an essential factor to consider. You should choose a dividing head that operates at different speeds to accommodate different applications.

6. Compatibility

The semi-universal dividing head should be compatible with your milling machine. You should choose one that fits well with the machine's spindle and table.

7. Brand and Price

The brand of the semi-universal dividing head is another important consideration. You should choose a reputable brand that has a track record of producing high-quality dividing heads. Price is also a significant factor to consider. You should choose a dividing head that fits within your budget.

In conclusion, selecting the best semi-universal dividing head for your milling machine requires careful consideration of several factors, including accuracy, material, size, speed, compatibility, brand, and price. By taking these factors into account, you can ensure that you choose a dividing head that will provide you with the best performance and value for your money.

For any further assistance or clarification you may feel free to revert us.

Looking forward to hearing from you soon.

Thanks with best regards

Surendra Kumar

For Pentagon Machines and Tools

57/1/01, F-II BLOCK Women's Entrepreneurs Ind CO-OP Soc. MIDC Pimpri Pune 411018

Mobile: +91 9022861033, 9373601875, 9890009604

Web: www.pentagonmachines.com

Email: pentagon@pentagonmachines.com

You Might Like Also

Universal Tools Sharpener

U2 /U3 Universal Tools Sharpener, with development of the carved industry, precisely designed by engineers. It is made up by main unit, wheel, spindle, drives, micro-feed and the grinding wheel dresser, knife the composition, structure, novel, modeling beautiful, high precision, good performance, easy to use, easy maintenance Read More

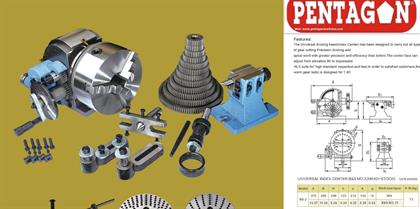

Universal and Semi Universal Dividing - Indexing heads

Semi and Universal Dividing Head is a simple Index Center and can be used for direct and indirect dividing.Complete the gear,face, flute processing and no need accessories, but the whole canstruction is the same as universal type The 24 quick-dividing holes can complete 2.3.46,8, 12,24 division indexing. Read More

End Mill Sharpeners

1. Portable idiot end mill sharpener, can grind 2-flute, 3-flute, 4-flute end mill 2. Grinding is accurate and rapid, easy operation with no skill to grind 3. With diamond grinding wheel 4. It can be equipped directly with an accurate angle Standard with SDC grinding wheel for the Carbide material, Optional CBN grinding wheel for the HSS material Read More

Vertical Knee type Milling Machine

Model X5036 Vertical Knee-type Milling Machine is suit for milling flat, inclined face, angle surface, slots by employing disc cutters, angular cutters, formed cutters and face metal milling cutters. When mounted with the index, the machine will be able to perform milling operations in gears, Cutter, helix groove, cam and tub wheel. Read More

Features and Technical Specification of PENTAGON Drilling Cum Milling Machine ZX6350C

Features and Technical Specification of PENTAGON Drilling Cum Milling Machine ZX6350C Read More

PENTAGON Drilling Milling Small machine

PENTAGON BRAND Drilling Milling machine model ZX50C table size 900x240 mm mounted on stand along with table with X axis auto table power feeder and swiveling table and spindle head along with all listed standard accessories Read More