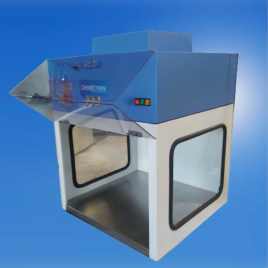

Wet Bench/Wet Process Station

₹ 62000.00

| Power: 120VAC |

| Drain: 2" NPT female |

| Nominal Voltage: 220- 230 volts |

| Dimension: 4' x 2' x 2' |

| More Specification(s) |

Looking for the latest Wet Bench/Wet Process Station price in Sonipat? WEIBER, one of Sonipat's best Wet Bench/Wet Process Station sellers & manufacturers, offers a wide range of Wet Bench/Wet Proce Read More...

GST No - 06AAKCA8493Q1ZQ

PLOT NO.126, PHASE-IV, SECTOR 56, KUNDLI, Sonipat, Haryana, 131028

| Others | |

|---|---|

| Brand | Weiber |

| Filter Type | 99.99% efficient HEPA |

| Power | 120VAC |

| Dimension | 4' x 2' x 2' |

| Air Flow | Unidirectional |

| Air Flow Control | Three Step Air Flow Speed Controller |

| Blower Assembly | Centrifugal Lubricated Bearing Type Isi Marked Assembly |

| Power Requirements | 500 watts -750 watts( model specific) |

| Nominal Voltage | 220- 230 volts |

| Frequency | 50 Hz |

| Construction | All stress-relieved white polypropylene |

| Exhaust | Ducted through a standard 10" (254 mm)-diameter flange positioned at the top rear of the cabinet |

| Drain | 2" NPT female |

| located at bottom of sub | deck plenum. |

| Illuminator | 800 lux |

| Controls | Instrument panel provides power switch |

| Noise Factor | 50 dBA |

Description

Fume hood wet process are specially designed for the use in semiconductor research and manufacturing where tanks, rinsers, heated baths require control modules. These equipments work with a lower exhaust blower to provide a means of removal of toxic fumes and odors. These equipments have a wide range of applications in several research and development organizations, medical laboratories, or for industrial applications. These equipments also known as Semi Conductor Wet Bench .

These self-contained Wet Processing Cabinets provide the perfect turnkey solution for a wide range of cleaning and processing requirements. This Cabinets also known as Wet Bench .

Available in polypropylene/SS-304 Wet Process Station from WEIBER manufactures both standard and customized microprocessor based Floor standing equipments. The fume hoods with PP construction are FRP lined and epoxy coated.

Standards Compiled:

- Federal Standard 209e

- Class 10 cleanliness

- ASHRAE Standard 110-1995

Special Features:

- Incorporates all processing components into one self-contained, easy-to-clean system

- Isolated control panel allows safe, convenient operation of baths, rinsers, and other process modules

- Select all-polypropylene or 304 stainless steel shell

- Standard system includes sliding access shield and fluorescent illuminator

- The Wet Processing Stations accommodate up to eight processing modules (rinsing tanks,etching baths, ultrasonic cleaners, hot plates, etc.).

- HEPA-filtered laminar flow fume hoods are suitable for use with trace metal applications. These units incorporate a top located filtration system powered by a dynamically balanced motorized impeller for even air distribution and excellent energy efficiency resulting in quiet operation.

- Corrosion resistant interiors and exteriors.

- Microprocessor based control system

Construction Details:

Fume hood wet process are manufactured with all white structural polypropylene/SS-304, which is corrosion resistant. All modular fume hoods are provided with sliding sash made of special grade shatter proof glass duly framed in wooden/ aluminum frame with sliding motion and counter weight balanced mechanism.

Noise and Sound Levels

Our stainless steel fume hoods are designed with lower noise levels and the performance of these fume hoods are comparatively better than the industry standards of 60db, and approximately 15cm distance from the sash.

Volume of exhaust

It is generally known that fume hoods are capable of maintaining a constant exhaust volume.

Illumination levels at work space

Our fume hoods wet process makes sure that a maximum of 800 lux light is available on the work table through diffuser fluorescent light arrangement.

Exhaust assembly

These fume hoods wet process are incorporated with an extremely durable and b exhaust system that generally persists a range of 500-1250 CM. These exhaust assembly comprises of balanced centrifugal impellers that are combined with a heavy duty three phase motor of Crompton greaves.

Exhaust ducting

These fume hoods wet process are also integrated with a FRP ducting of required dimension as per the requirements of the user.

WEIBER

WEIBER

PLOT NO.126, PHASE-IV, SECTOR 56, KUNDLI, Sonipat, Haryana, 131028

Send your enquiry to supplier

Related Videos

Questions for the Product Page

What is the current price of the Wet Bench/Wet Process Station?

The currently available price/cost of the Wet Bench/Wet Process Station on our AAJJO platform is ₹62000.00. For more accurate pricing, please request the quotation from the sellers by clicking on the “request callback” button on the Wet Bench/Wet Process Station detail page, and filling up details & requirements in the pop-up window.

Does Wet Bench/Wet Process Station good to purchase products in Sonipat?

Yes, we ensure our provided Wet Bench/Wet Process Station always remains the best and delivers the best to the users in Sonipat. The offered products are completely reliable because WEIBER is extremely experienced and offers good quality services. With an advanced range of specifications and brilliant features, provided Wet Bench/Wet Process Station is designed to ease workability, decrease expenses, and generate expected results.

Does WEIBER the best seller/supplier/manufacturer/dealer of Wet Bench/Wet Process Station in Sonipat?

No doubt, WEIBER is the best manufacturer or seller of the Wet Bench/Wet Process Station in Sonipat because of there immense expertise and quality offers. With expert knowledge of the sector and client-centric work mechanism, WEIBER ensure the best and most effective Wet Bench/Wet Process Station for its customers. And, with advanced accessories, satisfy the users with their desired results.

What payment methods are available for purchasing the Wet Bench/Wet Process Station?

To clarify your payment options for purchasing Wet Bench/Wet Process Station, please note that the available payment methods depend on the WEIBER preference. As the Wet Bench/Wet Process Station belongs entirely to the WEIBER, they can choose the mode of payment that suits them best. Currently, the available methods our sellers support are Cash, COD, Credit/Debit Cards, Digital Wallets, Bank transfer, etc.

What is the location of the WEIBER?

The location of the WEIBER is PLOT NO.126, PHASE-IV, SECTOR 56, KUNDLI, Sonipat, Haryana, 131028.

What is the GST Number of the WEIBER?

The GST Number of the WEIBER is 06AAKCA8493Q1ZQ.

How to Contact WEIBER for the purchase of Wet Bench/Wet Process Station?

There is only one convenient method to contact WEIBER. It begins with visiting Aajjo’s website and searching for the Wet Bench/Wet Process Station, then you have to click on the “request callback” button, and carefully have to fill up all the asked information on the pop-up screen. According to your provided location and requirements, our system provide you with Wet Bench/Wet Process Station sellers & dealers and their contact number, whom you can use to contact them.

What are the delivery options available for the Wet Bench/Wet Process Station?

To clarify the delivery options available for the Wet Bench/Wet Process Station, you have to visit Aajjo’s website and have to search for the product. In the product detail page, you will find a “request callback” button, after clicking on it, you will get a pop-up screen, where you have to fill up your quotation regarding Wet Bench/Wet Process Station, along with the asked details. This form allows you to provide your details and ask the Wet Bench/Wet Process Station seller about the most suitable and feasible transportation method for your purchase. By engaging with the seller through this form, you can discuss and finalize the best delivery options for you.

Featured Chart

Top Manufacturers of the Wet Bench/Wet Process Station

Here, we present a list of some of the top manufacturers of the Wet Bench/Wet Process Station listed with us. By, using the provide link, you can visit their personalized store page and check out their other quality products.

- FORTUNA TECHNOLOGY

- Whitenair Technologies

- Pure Air System

- Orbit Micro Instt

- Glowmax Engineers

- Best Scientific Co.

- Chemietron Clean Tech Private Limited

- S.K. SCIENTIFIC AND SURGICALS

- R Air Clean Pharma Equipment

- SR AIR SYSTEM

Wet Bench/Wet Process Station Prices Offered by Top Manufacturers in the Sonipat

There are a variety of manufacturers & sellers listed and deals on Wet Bench/Wet Process Station at Aajjo website. So, to make your purchase more feasible, here are a list of the prices that suited previous buyer requirements and are opted more in this Wet Bench/Wet Process Station category.

| FORTUNA TECHNOLOGY | ₹54000.00 |

| Whitenair Technologies | ₹65000.00 |

| Pure Air System | ₹86000.00 |

| Orbit Micro Instt | ₹20000.00 |

| Glowmax Engineers | ₹98000.00 |

| Best Scientific Co. | ₹39600.00 |

| Chemietron Clean Tech Private Limited | ₹25000.00 |

| S.K. SCIENTIFIC AND SURGICALS | ₹85000.00 |

| R Air Clean Pharma Equipment | ₹75000.00 |

| SR AIR SYSTEM | ₹62000.00 |

Find Best Price for

Copyrights © 2024 Aajjo Business Solutions Private Limited. All Rights Reserved.